November 2020 – Download as PDF (6 Pages)

Comments on an Impact Assessment on a potential implementing measure (EcoDesign Directive)

Concerning the energy efficiency of Electric Hand Dryers

Electric hand drying contributes to energy efficiency in a manyfold way.

eHA has worked constructively and contributed to the work of the “Ecodesign and Energy Labelling Preparatory Study on Hand Dryers (GROW Lot 12) | Final Report” (ICF Prep Study). eHA feels the need to point out a number of additional factors that were not subject to the named prep study, but that are crucial to properly assess the impact of potential on industry and consumer, notably:

a) Environmental considerations of hand dryers

b) Substitute products (notably paper towels)

c) Consumer behaviour

d) Resulting economic and environmental impact on the electric hand dryer industry

e) Actual expectable energy efficiency gains of potential measures

a) Environmental considerations of hand dryers

The hand dryer industry was the first industry to establish global standards with regards to products contained in the category relative to their testing and environmental effects throughout their life.

- Product Category Rules (PCR) are documents that provide rules, requirements, and guidelines for developing an Environmental Product Declaration (EPD) for a specific product category. They are a key part of ISO 14025 as they enable transparency and comparability between EPDs.

- Environmental Product Declarations (EPDs) are a standardized way of quantifying the environmental impact of a product by studying the raw materials and energy consumption during its production, use and disposal.

With over a century of experience developing more than 1,500 standards, UL Environment, a business division of Underwriters’ Laboratories (UL) was chosen to develop and publish the PCR. The rule established product evaluation methods used to determine key values such as dry time and energy consumption through industry consensus.

Prior to the establishment of the PCR for the industry, an American hand dryer manufacturer conducted a third-party Life Cycle Assessment (LCA) (peer reviewed to ISO 14040 standards) that confirmed between a 50–75 percent reduction in the carbon footprint of hand drying—even when compared to 100 percent recycled paper towels. Now, using standardized and agreed upon methodology, all hand dryer manufacturers are able to test their products to the same rigorous standards, with results—substantiated by a credible leading organization—confirming the environmental benefits of hand dryers.

b) Paper towels constitute poor substitute products

One ton of virgin paper towels consumes 17 trees, uses 75,8 m3 of water are consumed and polluted. To reprocess this water, a lot of energy is needed. Furthermore, this ton of paper produces more than 3 tons of CO2 emissions, and requires 12 m2 of landfill space. Three more reasons:

- Paper Towels cannot be recycled

Paper towels are contaminated waste therefore they all have to end up in landfill. Although paper towels can be made from previously recycled paper, they are usually the last paper product to be made in the chain. This means that the paper they are made from has been recycled up to seven times before. The fibres are just too short in paper towels to be used again.

- Decomposing paper hand towels contribute to global warming

In the USA alone, 6,500,000 TONS of paper towels are sent to landfills each year. The decay of paper products and landfills in general produces methane gases which are 28 times more potent than carbon dioxide, therefore a real threat to global warming. They are also often put in plastic bags, creating further downstream problems in the recycling process.

- The average paper towel generates 7.5gms/CO2 or 22.5 gms/CO2 per dry.

Life Cycle analysis shows that the effects of felling raw materials, transportation, manufacturing, packaging, storage on a constant loop, significantly produces a lot of CO2 into the atmosphere. Also, to make one ton of paper towels, 17 trees are cut down and 20,000 gallons of water are consumed and polluted.

c) Consumer behavior

The measures proposed in the study cannot be stomached by the industry without an increase in cost for consumers. For instance, the proposed measures are likely to lead intentionally to the elimination of a high number of lower-priced – so-called category 1 – hand dryers, as those dryers are less energy-efficient. Our experience shows that the loss of these sales will not be compensated with sales in dryers that meet higher energy efficiency levels, but part of these sales will be replaced by another drying system with a lower initial investment: Paper towel dispensers.

Hand dryers and paper towels are fully substitutable products. In the long term, hand dryers are less expensive, but the short-term investment is lower for paper towels. Anyone looking for a drying system that requires a low minimum investment and under the assumption that they do not have an economical dryer, will buy a paper dispenser (sometimes given away with the contract to buy paper for a long-term lease such as 60 months). Although companies concentrate their promotion almost only on high-speed dryers, category 1 dryers are still a very popular alternative in the EU. The main reasons are:

- Budget solution

- Quieter

- Suitable for low/medium traffic installations

- Longer life span. Easier to repair. Supporting circular economy.

d) Resulting impact on the Hand dryer industry

The hand drying businesses in Europe are family-driven and comprise a mainly medium-sized industry. The suggested Energy Label and saving efforts might reduce limited energy and thus GHG emissions but increase huge amount of cost on hand dryer manufacturers, which most are SME.

The safety, hygiene and sustainability of products have always been the major targets when developing and manufacturing hand dryers. This is why products of European SMEs have obtained quality and sustainability certificates in Europe like GS, Blue Engel, and other certificates worldwide.

The impact of suggested measures e.g. reduced stand-by power to max. 0.5 W would lead to an immense reduction of revenues. The consequences are:

- Less resources to invest in new technology

- Reduced competitiveness in the market

- Job reduction

- Possible closure of companies

eHA Member`s estimate:

We estimated the market share loss to be 20%-30% due to the category 1 dryers shift to paper, and maybe some of the category 2-4 dryers also being substituted by paper.

It usually takes 6 to 9 month to payback when comparing paper towel dispenser and hand dryer cost, but when hand dryer price increased 20%, the payback time may be prolonged to 1 year and some of the customers will then choose paper.

Another Assessment:

We consider that by eliminating category 1 dryers from the market, there will be a 60% substitution effect. In other words, 6 out of every 10 installations that have bought a category 1 dryer will buy paper. That will mean a loss of market share of between 25-30%.

If the MEPS (Minimum Energy Performance Standard) and Labeling are implemented, we estimate an increase in the cost of category 2 and 4 dryers by 20-25%. This will push approximately 10% of those who would have bought a high-speed dryer, choosing paper.

It should be noted that in 2020 the hospitality sector has been affected very hard by the COVID crisis. Hotels, bars and restaurants, with medium/low traffic areas, are one of the main applications for category 1 dryers. These installations will be particularly sensitive to price/costs and will choose drying systems that represent the lowest initial investment.

e) Actual impact on efficiency gains that can be expected

The European Commission must bear in mind that a negative impact on the hand dryer industry could be very high, while the actual energy efficiency gains are likely to be minimal. We elaborate a few examples below:

Energy Label

The energy label requires to reduce the energy, but according to the current technology limitation, the energy that can be reduced is limited and requires high costs. For example, the suggested stand by power is max 0.5w, currently 31% of hand dryers already fall within the range, while 69% of hand dryers are in the range of 0.5–2w. In order to adjust the standby power, it requires PCB (Printed Circuit Board) redesign, and the possible costs and efforts needed for this could be as follows:

- Safety approvals fee

- To change PCB board means most of our safety approvals need to be re-applied. In general, a hand dryer will have 6-8 safety approvals, and roughly it will cost EUR 25,000 each model, and we currently sell over 15 different BC1 dryer models to Europe, which means to change the standby power, the reapplied safety approval fee is EUR 375,000.

- Long test time

- Updating PCB requires quality assurance. The longest test should be life cycles test which takes about 6-9 months. And to gain each safety approvals takes 2-4 months.

- Replacement & stock cost

- For the current timeframe of energy label, manufactures need to replace the current dryers on the market and in the stock. Take the study figure for example, to replace the least efficient (25%) BC1 hand dryer PCB will cost (PCB cost + labor cost)*(2020 BC1 stock*25%), which will be (27.25+128.58)*(5,179,000*0.25) = EUR 201,760,892.5.

Source: ExcelDryer (eHA Member)

Lack of standards to measure the drying time

To establish a limit of 10Wh per cycle, the consultant took in consideration the drying time values published by the various manufacturer. Since there are no clear standards, each manufacturer has a different way of measuring drying time. Additionally, the drying time varies a lot depending on the type of skin, size of the hands, soap residues etc.

A Spanish eHA member company has made some drying tests taking as reference what was proposed in the Preparatory Study: Rest of water 25gr. This is the result with different dryers and two different users:

| DryTime | Person 1 | Person 2 | |

| Dryer 1 | 25 s | 0,41 gr. | 1,24 gr. |

| Dryer 2 | 25 s | 0,11 gr. | 0,41 gr. |

| Dryer 3 | 15 s | 0,18 gr. | 0,66 gr. |

| Dryer 4 | 15 s | 0,12 gr. | 0,19 gr. |

Without a definition of drying time all the projections on efficiency gains are questionable.

Conclusions

All measures taken to further reduce energy use of warm air dryers need to consider contextual factors, especially the following:

- Increasing use of energy by consumers due to substitution of products

- Job losses in the relevant European SME sector

- New environmental problems with regard to water, waste, additional GHG emissions

- Hygienical problems

The latter is quite relevant during the Corona pandemic. Experts from leading health organizations including the World Health Organization (WHO) and Centers for Disease Control and Prevention (CDC) state that proper hand hygiene is the best defense against the spread of germs, like coronavirus. Furthermore, all are in agreement that proper hand hygiene consists of thoroughly washing and completely drying hands.

Specifically, the World Health Organization has stated that proper hand hygiene is the best defense against the spread of the coronavirus and other germs, recommending that everyone “frequently clean [their] hands…” and “dry [them] thoroughly by using paper towels or a warm air dryer.” The Centers for Disease Control and Prevention calls hand hygiene a “do-it-yourself-vaccine,” and reports that, “both [clean towels or air hand dryers] are effective ways to dry hands.”

The hand dryer industry has a vivid interest in improvements of their products. The innovative power has been demonstrated over the past decades. However, the real costs – especially environmental costs – need to be considered by examining and comparing two completely different systems that serve as substitute products for each other.

Coronavirus and Electric Hand Dryers in Public Washrooms

Coronavirus and Electric Hand Dryers in Public Washrooms

June 2020

Position Paper – Download as PDF (2 Pages)

Whilst the world experiences the global COVID-19 pandemic, it is good to see improved hygiene standards being implemented in public buildings, and that hand dryers are contributing to fulfil these standards in an efficient and sustainable manner.

Together with hygiene, the protection of the environment is a priority for our industry, and electric hand dryers form part of a global solution for energy efficient and environmentally friendly products, as opposed to non-sustainable and single-use options.

This paper demonstrates the electric Handdryer Association’s (eHA) continued commitment to hygiene, sustainability and efficiency in the face of the ongoing pandemic, and explains how hand dryers are not only key in the fight against coronavirus, but also for long-term economic business survival and sustainability:

- Hygiene – Official Recommendations vs. incorrect information and unreliable studies – electric hand dryers are a hygienic hand drying solution.

In recent years, particularly in recent months since the emergence of COVID-19, alarmist rumours about hygiene and the use of hand dryers have been circulated, leading to misinformation and confusion. However, several in-depth, independent studies over the last 30 years have shown that no single drying system (paper towels or electric hand dryers) is more hygienic than another.

In the face of the COVID-19-crisis, the US Centers for Disease Control & Prevention (CDC), and scientists at Johns Hopkins University have all categorically confirmed and gone on record to say that hand dryers do not spread the Coronavirus.

The World Health Organisation (WHO) has also given a clear message in its recommendations to combat the coronavirus – ‘once your hands are washed, you should dry them thoroughly using paper towels or a warm air dryer’.

Since threats like COVID-19 can lead to the circulation of misinformation, it is important to trust information only from reputable health organisations and government sources such as the CDC and the WHO.

Additionally, the hand dryer industry has added new features to dryers (e.g. HEPA filters, antibacterial materials, ionizers) to further improve hygiene for sensitive locations.

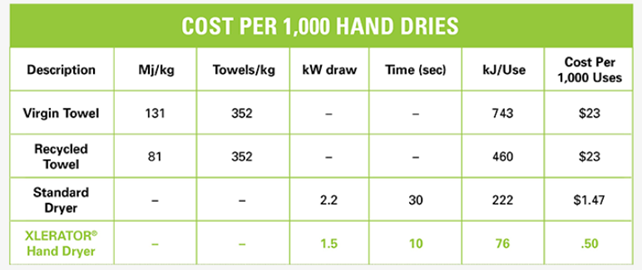

- The use of electric hand dryers compared to other hand drying methods contributes to a low carbon economy.

Studies show that using hand dryers produces up-to 75% less carbon emissions than other systems. Additionally, our collective products have received a number of green certifications and awards. Hand dryers meet the requirements of circular economy. The design and manufacture of the dryers allow for repair, life extension and the posterior recycling of components.

- The electric hand dryer has also proven to be the most economical hand drying system.

The use of paper or textile roll towels involves a significantly higher operating cost when factoring in purchasing, stocking and disposing of the cloth or paper towels, along with the maintenance to refill the dispensers and dispose of used towels. In the coming months, cost savings will be essential for many businesses to survive. Choosing hand dryers for public locations can help meet this goal, particularly high speed, energy efficient classes of dryers.

- It is in the EU’s interest to preserve their domestic hand dryer industry.

The hand dryer industry consists of mostly small and medium-sized companies, many of which are headquartered and manufacture within the EU. This industry has always been close to the customer, offering electrical safe products, which comply with the European safety norms. The industry continues to invest in new technologies contributing to the economy in the different countries in terms of employment and innovation.

April 2019

eHA-Position Paper on electric Hand Drying

The electric Hand Dryer Association (eHA) is pleased to work with European Commission to achieve its objectives for the Eco Design Initiative and adopting a Clean Energy policy. We believe our collective efforts and technological developments of recent years have been aligned with these goals. In connection with the 2016-2019 Work Plan, the eHA would like to highlight the below key success factors as relates to our industry. We hope to demonstrate that electric hand dryers can play a meaningful role in allowing the EU to successfully transition to a low-carbon economy.

Key success factors for hand drying regulation:

1. Electric hand dryers have favorable characteristics as compared to other hand drying methods as discussed below.

2. The use of electric hand dryers compared to other hand drying methods contributes to a low carbon economy. Studies show that using hand dryers as a drying system produces up to 75% less carbon emissions than other systems

3. The electric hand dryer has also proven to be the most economical hand drying system. Controlling public spending is a continuous objective within the EU, and specifically for the 2016-2019 Work Plan. Choosing hand dryers for public places can help meet this goal, particularly high speed, energy efficient classes of dryers.

4. Electric hand dryers are a hygienic hand drying solution. However, several studies have been published that show that no one drying system is more hygienic than another. Additionally, the industry has added new features to dryers (e.g. HEPA filters, antibacterial materials) to further improve their hygiene for sensitive locations.

5. Hand dryers should not be regulated for sound levels beyond existing statutes. It is generally the case that the speed of a hand dryer is directly correlated with both energy efficiency and noise level, such that a faster dryer saves more energy, but is also louder.

6. There are many types of hand dryers. The pending legislation must be carefully crafted to appropriately consider each option.

7. It is in the EU’s interest to preserve their domestic hand dryer industry. The industry consists of mostly small and medium-sized companies many of which are headquartered and manufacture within the EU. The implementation of the regulation should enable them to continue to have the necessary resources to maintain their contribution to the EU’s economy in terms of employment and innovation.